E-Sourcing and E-Procurement applied: How structured RFx-Processes save manufacturing costs and optimize your supplier network

Since the beginning of the 90s, the internet has evolved into a vast global network with an unmatched variety of use cases. Unsurprisingly, it has also found its way into many areas of business, including the manufacturing industry. In an effort to make the manufacturing industry more global and efficient, many new ways of managing production processes have emerged. In specific, this article will target the importance of E-Sourcing and E-Procurement, especially considering the advantages that arise from applying a structured RFx-process.

The importance of E-Sourcing and E-Procurement in modern-day manufacturing

The term E-Sourcing describes the strategic use of web-based applications and decision tools to streamline and enhance the sourcing process. It includes determining what your company needs to buy, identifying the location of current and potential suppliers as well as gathering information about them. The goals of E-Sourcing are to save material costs and improve your supplier management. In general, the sourcing phase is known to have a bigger potential for savings than the procurement phase. Studies (cp. Gaani 2019) have shown that E-Sourcing benefits buyers by reducing search and information cost, saving process costs, and supporting a more efficient procurement process. Even more advantages include enabling new business development and more effective supplier sourcing. Not only that, but it also improves transparency both on the supplier side and on the buyer side and thus enhances the relationship between both parties.

E-Procurement is what follows the E-Sourcing process and encompasses the operational aspects of purchasing. It focuses on the purchasing of products and services through digital networks and thus saving costs by improving process efficiency. Therefore, it integrates innovative information and communication technologies. E-Procurement includes order placement, receipting, managing payments and invoice reconciliation.

The advantages of making your procurement more digital include greater visibility of information on on-contract and off-contract spendings as well as having an overview of the times to pay invoices. It also enhances a company’s flexibility in the purchasing process and supports automation by providing internal catalogues or templates for your orders. Overall, E-Procurement leads to a better and centralized access to all your data connected to your operational purchasing, while also saving costs and facilitating budgeting.

Now that we covered the basics of E-Sourcing and E-Procurement, you might wonder how you can implement these kinds of processes to reap these benefits for your own company. The answer to this is implementing a structured RFx-process.

RFx as part of the E-Sourcing and E-Procurement processes

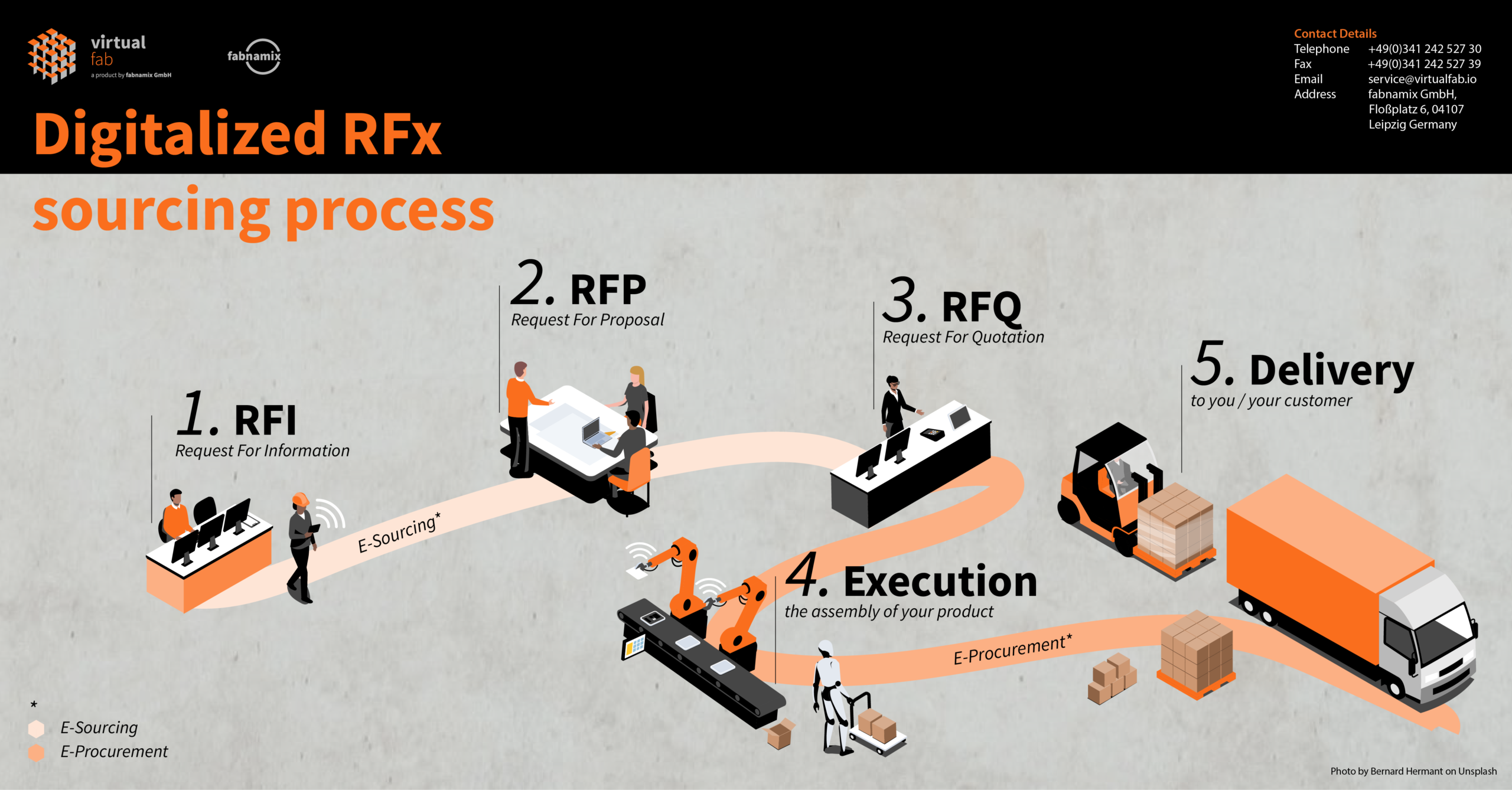

RFx is a collective term for multiple steps in the sourcing process, starting with Request for Information (RFI), followed by Request for Proposal (RFP) and ending with Request for Quotation (RFQ). Following this order, the RFx process is used to solicit information about potential suppliers (RFI), get in contact with them to discuss your product specifications (RFP) and potentially set up a new contract (RFQ). Accordingly, a well structured RFx process can support your E-Sourcing efforts from the point of supplier assessment, which would be the RFI-phase, all the way through to contract negotiations and setup (RFQ) as the transition point to E-Procurement.

To start out your sourcing process, the first thing you want to do is having a list of requirements of the product you are looking to buy. Naturally, this should be followed by drafting a blank contract, excluding the supplier specifics, product and service codes and the prices. Doing so will help your sourcing team to keep a better overview of what exactly they are seeking as an outcome of your sourcing project.

The goal of the RFI process is to qualify suitable providers of products and/or services for your company. Therefore, this qualification should not only focus on technical requirements, but also on business-related and cultural requirements. To have a long and successful connection with your suppliers, it is crucial to ensure that they are on the same page as you when it comes to business goals and cultural values.

The qualification of potentials suppliers may take various forms, such as looking at previous suppliers, existing bidders, doing market research and receiving self-nominations from suppliers. Following this research process, a first list of potential suppliers will be created. At this point, the buyer does not commit to selecting any supplier in specific, but rather it is a compilation of information for the purpose of evaluating the possibility of dealing with a supplier. Accordingly, the RFI process is a completely nonbinding mechanism.

After you create a first list of potential suppliers, the qualification can be followed up by multiple rounds of gathering more detailed information. Conducting more research is key to ensure that the supplier is likely able to provide your required goods/services, at a sufficient level of quality, in the desired timeframe and in harmony with your organizational policies, your brand and your company culture.

Doing a more in-depth supplier qualification process, while it may be time intensive, is important to ensure that every supplier you select for bidding is capable of meeting your organizational needs and once a supplier has been chosen, you can simply focus on negotiating the final terms and conditions of the deal. Proper qualification ensures that your company will be able to identify which suppliers cannot service 100% of your requirements. After completing multiple rounds of your selecting process, the RFI phase will be finished by creating a shortlist of all suppliers that are likely to meet all your requirements. This shortlist will typically include three to five suppliers.

RFP – Request for Proposal

After shortlisting potential suppliers, your company will want to get in contact with the suppliers you pre-selected and send them your list of requirements. This includes the complete description of the core product and service specifications that will be put out to bid as well as notifying them of all mandatory terms and conditions that the supplier will need to agree to. While you are sending out this information, you will want to ensure the security of your data. The best solution for this is using data rooms, that make sure your data is encrypted and safely stored.

However, the most crucial part of the RFx process lies in the discussions about product improvements that take place during the RFP phase. The goal of these modifications is to decrease the production cost and optimize your product upfront. Following this principle, there may be multiple release cycles of improved product suggestions until it reaches a fully optimized state. This can be a great opportunity for suppliers to showcase their capabilities of creating custom and innovative proposals and show you opportunities for cost reduction. In case there are multiple options with different trade-offs, the buyer will need more detailed specifications to be able to make a decision about the feasibility and appropriateness of the supplier’s bid. The RFP may or may not contain cost or bid information, however when the buyer has decided on a feasible option, another RFP or RFQ with exact specifications may be issued.

RFQ – Request for Quotation

The last step of the RFx process is the RFQ, which is all about collecting bids from the suppliers you selected in the previous stage and enter direct negotiation with them. At this point, there will be no more modification on the product data, as it has already been optimized during RFP. The suppliers must submit quotes that have to meet the specifications that you agreed on during RFP. The buyer will then commit to awarding the contract to the lowest cost supplier. The signing of the contract marks the end of the RFQ phase and now the execution phase will begin.

Why you should apply a structured RFx process into your sourcing efforts

As already discussed, the RFx process is a highly efficient procedure that can improve your overall sourcing efforts. The biggest advantages stem from the potential of saving costs during the RFP phase by optimizing your product. Doing this optimization thoroughly enough can reward you with a long-term reduction in manufacturing costs.

Additionally, a proper RFI process also enables you to find the right supplier that matches your company’s ethics and goals and is focused on mutual success. Naturally, this ensures satisfaction for both sides and encourages long-term contracts. Even though conducting a thorough RFI may be time-intensive, it will pay off long-term since it lowers the chances of having to find alternative suppliers later on.

How virtualfab can assist you in the RFx process

We are developing a solution to make your E-Sourcing as effortless as possible, including the full RFx process. Our software virtualfab enables you to have a centralized platform to research suppliers and easily find detailed information about each producer. We are also looking to facilitate communication once you reach the RFP phase with shared team chats, which can be joined by multiple team members on the customer and producer side. Therefore, you can save time and communicate more efficiently with each other. Furthermore, encrypted file transfer ensure the safety of the data while still making them easily available to the recipients of the information.

Did we pique your interest?

If you would like to learn more about our solution, get in contact with us and we will be happy to have a chat with you!

Sources:

Gaani, A. M. (2019) The effect of E-Sourcing on cost reduction in a manufacturing firm. A case study: Century Bottling Company LTD. Kampala International University.

Figueiredo, J.; Sampaio, L. (2011) E-Sourcing Electronic Platforms in Real Business. Technological University of Lisbon.

Lamoureux, M. (2018) The Strategic Sourcing Lifecycle: A Brief Introduction. Tess Academy.