Simplify your contract manufacturing

virtualfab is all you need to get fabless manufacturing done.

Supplier collaboration, process planning, tendering, and order execution, control your global supply chain from one secure platform.

Simplify your contract manufacturing

virtualfab is all you need to get fabless manufacturing done.

Supplier collaboration, process planning, tendering, and order execution, control your global supply chain from one secure platform.

Build on the foundation of the digital twin technology jointly with powerful Industrial Digital Twin Association consortium partners

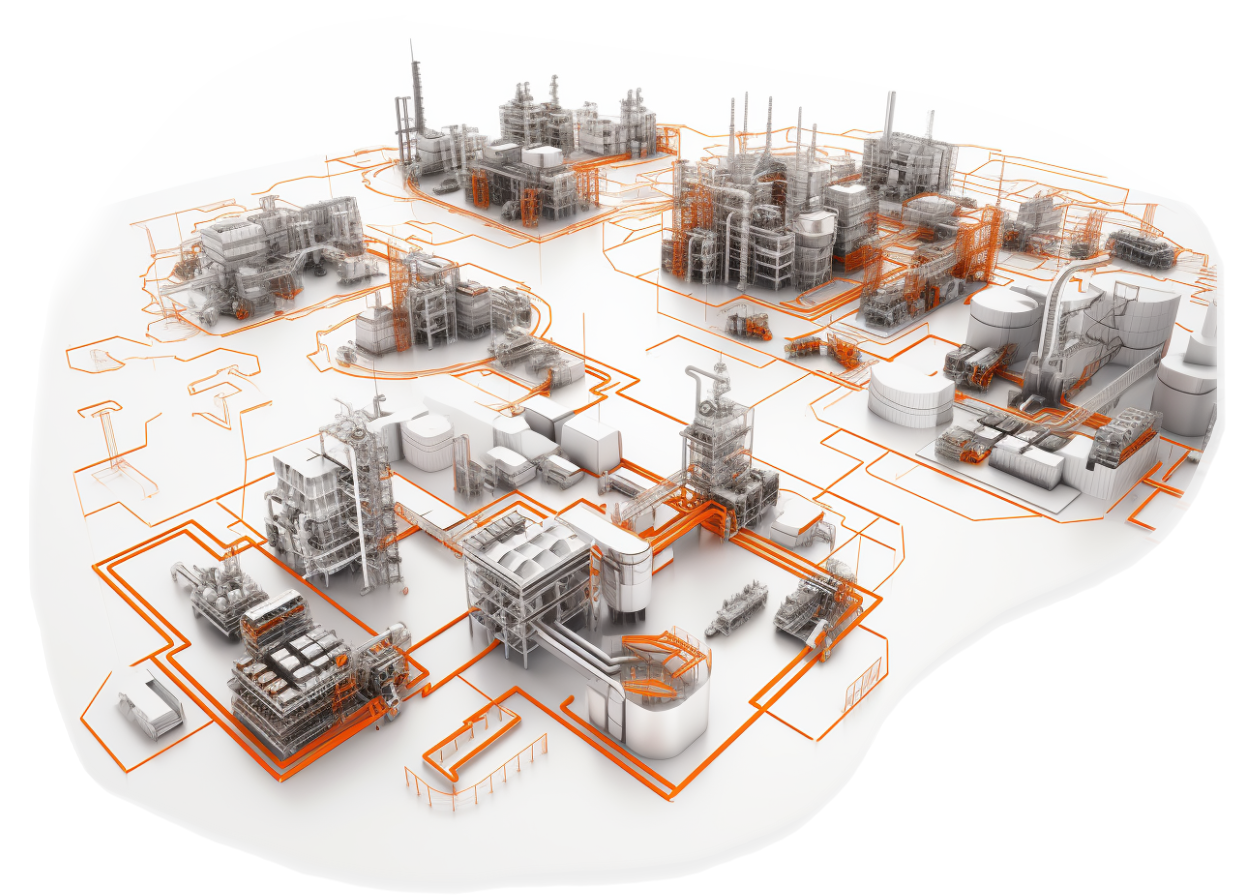

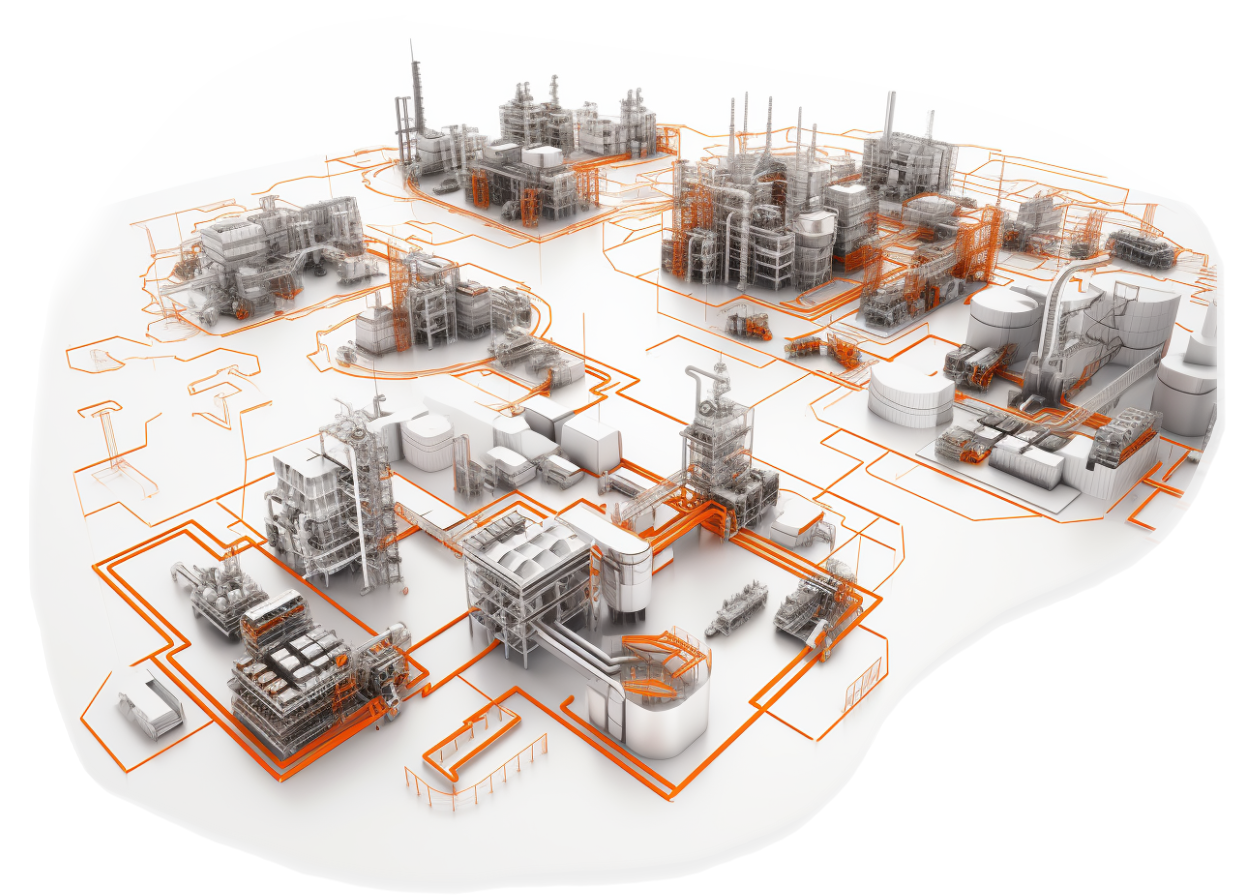

virtualfab enables industrial companies to manufacture fabless

The IT software landscape of industrial companies often consists of dozens of individual tools. Grown over time most of the stack is hardly compatible. So your employees work hard to get information from one application to another to orchestrate manufacturing processes. The common goal: deliver your products on time.

virtualfab frees your time by connecting people and software systems across company borders. Your engineering department contributes design data, purchasing controls supplier communication, and your webshop and fulfillment are directly connected. This is when the real magic happens: your employees are freed of repetitive tasks, data flow is automated, and manufacturing and delivery of your product are assured. Your company is ready to tackle to future.

Resilience

Real- time insights and transparency increase your flexibility to predict, adjust and optimize your production chains anytime.

Teamwork

Work on manufacturing projects together with your team and partners – with shared data and communication rooms.

Scalability

Scale your optimized supply chain according to the demand. Stay flexible and only pay for what you need .

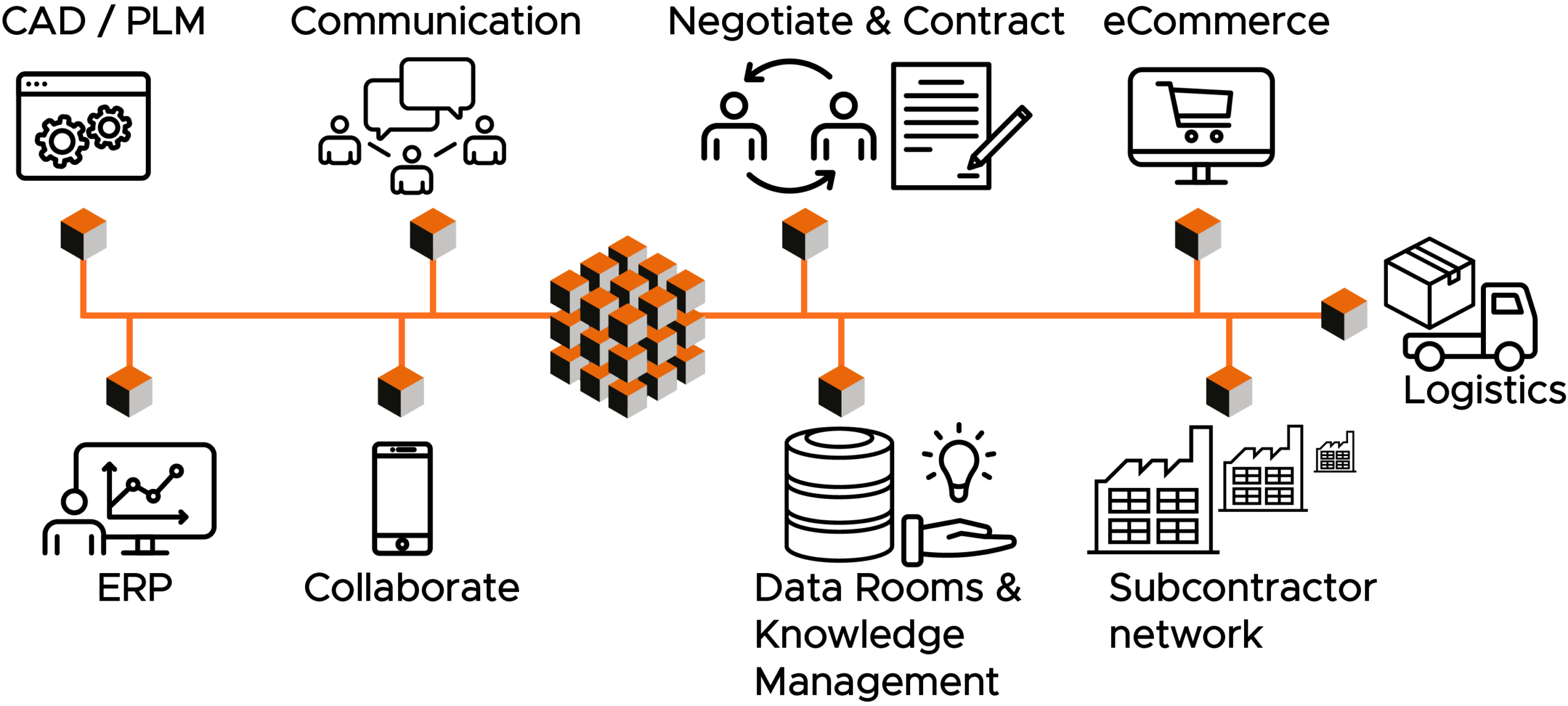

Finally, full control of your supply chain in one place

Contract manufacturing is a team play

United by one goal: get your products shipped in time and cost.

Gather all departments and roles in one place to ensure a seamless flow of information. Engineering to logistics: everyone must be involved.

Manufacturing process planning

Use virtualfab’s graphical editor to plan your supply chain. Each node represents one or more suppliers you can directly collaborate with. You gain visibility throughout your entire supply chain and prevent to miss important orders and deliveries.

Centralized communication & Knowledge management

Text with all involved suppliers and your team from within one tool. Secure data rooms preserve all the valueable knowledge and create legally binding documentation of agreements made with suppliers. No spam, no malware, only purely business-related messages.

What our customers say

Highly specialized supply partners and direct access to all assemblies in our own

virtualfab – there‘s no easier way to outsource your manufacturing today.

When working with virtualfab, I particularly liked the smooth service. They offer direct access to all components of the product, so that adjustments can be

communicated quickly. From the idea phase to implementation, everything is centrally organized.

I can easily scale my capacities to meet my customers demand by attaching a virtualfab to my in-house facilities.

Schedule your free demo

See if our software is the right match for you, risk-free and without obligation.